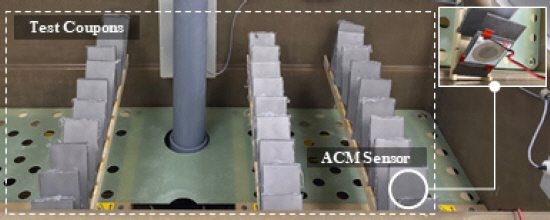

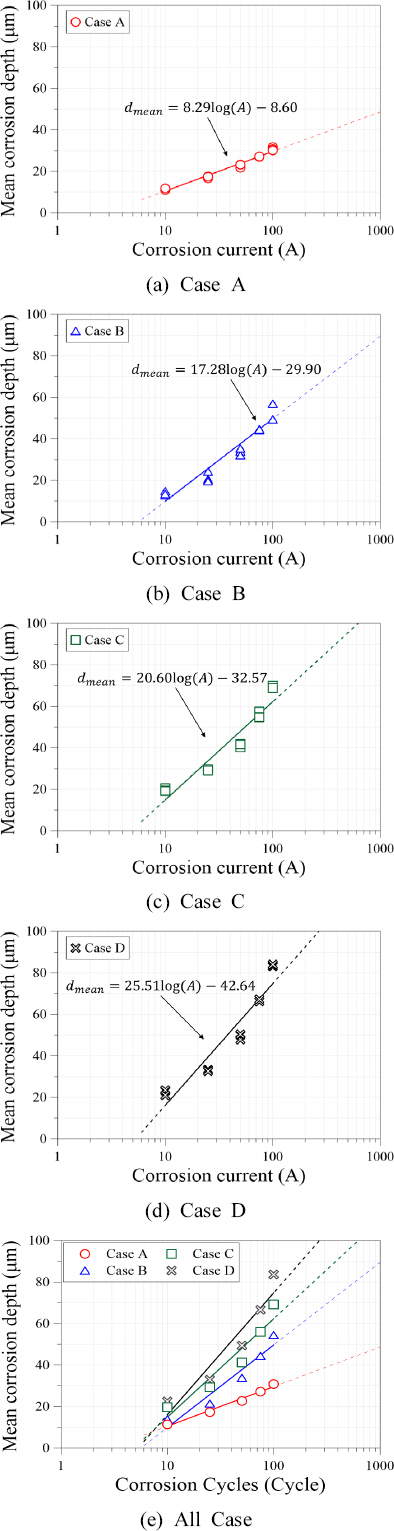

1. Ahn, J.H, Jeon, S.H, Seong, T.R, and Jeong, Y.S (2019) Estimation of corrosion damage rate using corrosion current depending on atmospheric corrosion environment.

Journal of Korean Society of Steel Construction, Vol. 31, No. 4, pp. 253-260.

2. Ahn, J.H, Jeong, Y.S, Kim, I.T, Jeon, S.H, and Park, C.H (2019) A method for estimating time-dependent corrosion depth of carbon and weathering steel using an atmospheric corrosion monitor sensor.

Sensors, Vol. 19, No. 6, pp. 1416.

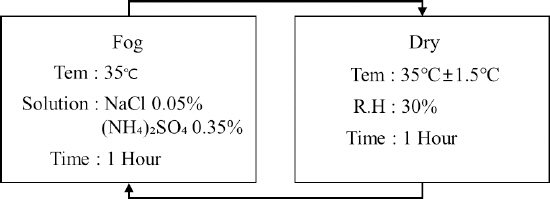

3. ASTM B117-19 (2019). Standard practice for operating salt spray (fog) apparatus. American Society of Testing Materials International.

4. ASTM G85-19 (2019). Standard practice for modified salt spray (fog) testing - Annex A5, dilute electrolyte cyclic fog dry test. American Society of Testing Materials International.

5. Ha, M.G, Jeon, S.H, Jeong, Y.S, Mha, H.S, and Ahn, J.H (2020) Corrosion environment monitoring of local structural members of a steel truss bridge under a marine environment.

International Journal of Steel Structures, Vol. 21, No. 1, pp. 167-177.

6. ISO 16701:2015 (2020). Corrosion of metals and alloys - Corrosion in artificial atmosphere - Accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution. International Organization for Standardization.

7. Jeon, S.H, Ha, M.G, Jeong, Y.S, and Ahn, J.H (2019) Evaluation of corrosion damage of structural steel depending on atmospheric exposure test.

Journal of Korean Society of Steel Construction, Vol. 31, No. 4, pp. 245-252.

8. Jeong, Y.S, Kim, M.J, Jeon, S.H, Ahn, J.H, and Kim, I.T (2019) Suggestion of deterioration curve for new-type coating on atmospheric environment by acceleration corrosion test. Journal of the Korea Institute for Structural Maintenance and Inspection, Vol. 23, No. 2, pp. 75-83.

9. Jin, Y.H, Ha, M.G, Jeong, Y.S, and Ahn, J.H (2020) Relative corrosion environment conditions of steel box members examined by corrosion current measurement. Journal of the Korea Institute for Structural Maintenance and Inspection, Vol. 24, No. 6, pp. 171-179.

10. JWTCS1001 (2009) The method of accelerated cyclic corrosion test - 1% salt spray. Japan Weathering Test Center. 2009. Japan (in Japanese).

11. Kim, H.J, Lee, H.C, Jun, S.K, and Lee, S.H (2007) Damage estimation of steel bridge members by fatigue vulnerability curves considering deterioration due to corrosion with time. Journal of the Korean Society of Hazard Mitigation, Vol. 7, No. 4, pp. 1-12.

12. Kim, I.T, and Itoh, Y (2007) Corrosion durability evaluation of uncoated structural steel using accelerated exposure tests. Journal of Korean Society of Steel Construction, Vol. 19, No. 1, pp. 79-86.

13. KS D 3515 (2018). Rolled steel for welded structures. Korea (in Korean).

14. KS D ISO 8407:2009 (2019). Corrosion of metals and alloys - Removal of corrosion products from corrosion test specimens. Korea (in Korean).

15. KS M ISO 11997-1:2017 (2021). Paint and varmishes - Determination of resistance to cyclic corrosion conditions - Part 1:Wet (salt fog)/dry/humid. Korea (in Korean).

16. Lee, Y.B, Jeong, Y.S, Seong, T.R, and Ahn, J.H (2018) Estimation of mean corrosion depth of structural steel using thickness of corrosion products.

Journal of Korean Society of Steel Construction, Vol. 30, No. 3, pp. 153-161.

17. Li, X, Cao, G, Guo, M, Peng, C, Peng, Y, Ma, K, and Wang, Z (2021) Influence of Cl

- and SO

2 on carbon steel Q235, pipeline steel L415 and pressure vessel steel 16MnNi corrosion behavior in industrial and marine atmosphere environment.

International Journal of Electrochemical Science, Vol. 16, No. 12, pp. 21126.

18. Mizuno, D, Suzuke, S, Fujita, S, and Haru, N (2014) Corrosion monitoring and materials selection for automotive environments by using atmospheric corrosion monitor (ACM) sensor.

Corrosion Science, Vol. 83, pp. 217-225.

19. Park, K.M, Kim, I.T, Choi, Y.T, Yoo, H, and Jeong, Y.S (2022) Characteristic of airborne sea salt and deposited salt on a offshore steel bridge considering environmental changes.

Journal of Korean Society of Steel Construction, Vol. 34, No. 6, pp. 373-381.

20. Pei, Z, Cheng, X, Yang, X, Li, Q, Xia, C, Zhang, D, and Li, X (2021) Understanding environmental impacts on initial atmospheric corrosion based on corrosion monitoring sensors.

Journal of Materials Science &Technology, Vol. 64, pp. 214-221.

21. Vincent, L.D (2001). Surface preparation standards, paper presented at NACE corrosion conference 2001. USA: National Association of Corrosion Engineers.